Get Welder Performance Qualification Record Form in PDF

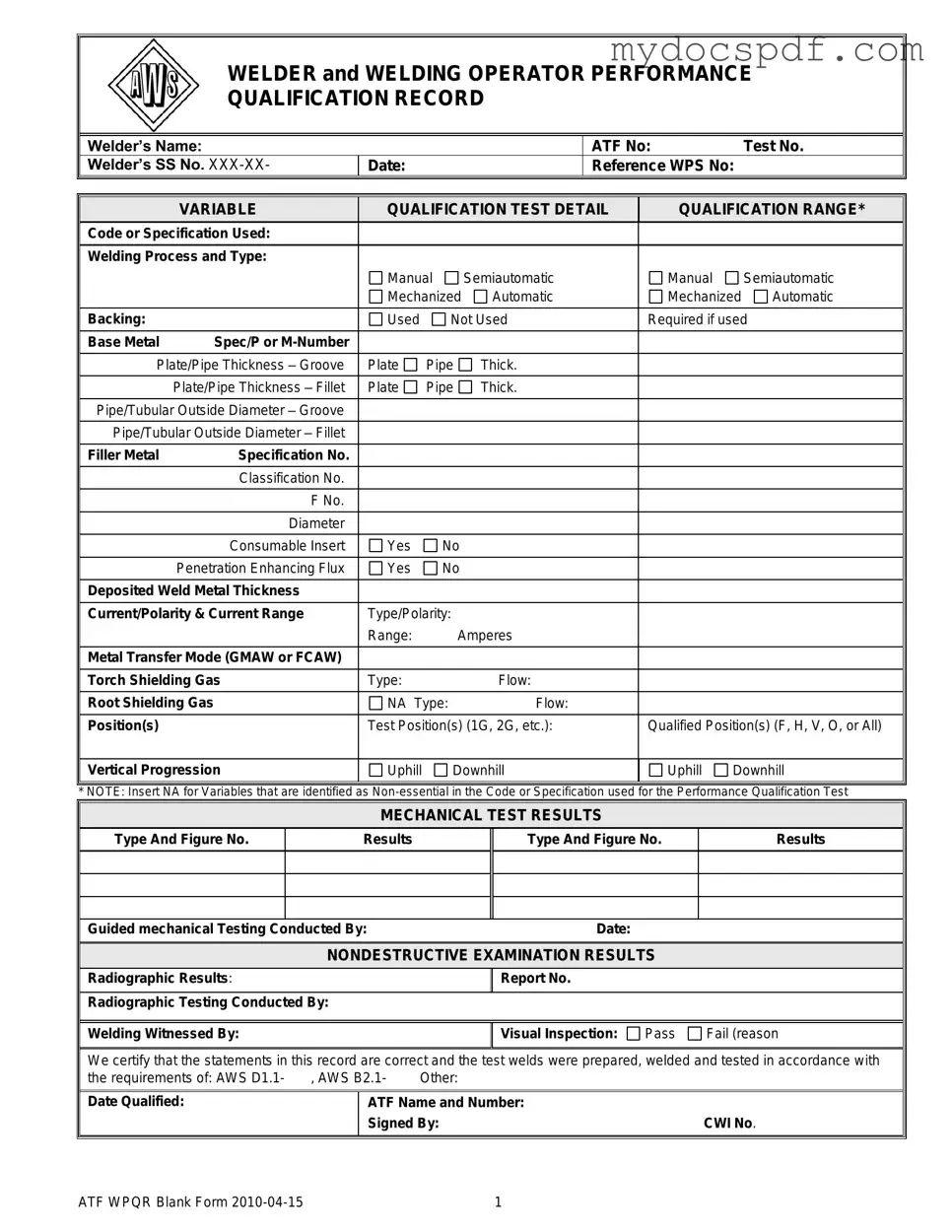

The Welder Performance Qualification Record form is an essential document used to verify a welder's skills and capabilities in various welding processes. This form captures key information, including the welder's name, identification numbers, and the specific test details that validate their qualifications. It outlines the welding processes employed, such as manual, semiautomatic, and automatic techniques, along with the types of base metals and filler materials used during testing. The form also specifies the thickness of the materials and the positions in which the welding was performed, providing a comprehensive overview of the welder's expertise. Additionally, it includes results from mechanical tests and non-destructive examinations, ensuring that the welds meet industry standards. By documenting all relevant qualifications and test results, this record serves as a crucial tool for employers and regulatory bodies to assess the competency of welders in various applications. Ultimately, the Welder Performance Qualification Record form plays a vital role in maintaining safety and quality in the welding industry.

Dos and Don'ts

When filling out the Welder Performance Qualification Record form, it’s important to follow some key guidelines. Here are four things you should and shouldn't do:

- Do fill in all required fields completely and accurately.

- Do double-check the welding process and type to ensure it matches the specifications.

- Don't leave any sections blank unless they are marked as non-essential.

- Don't forget to sign the form and include the date of qualification.

Document Attributes

| Fact Name | Description |

|---|---|

| Purpose | The Welder Performance Qualification Record form documents a welder's qualifications and skills, ensuring they meet industry standards for welding processes. |

| Key Information | Essential details include the welder's name, social security number, test number, and the welding procedure specification (WPS) number. |

| Testing Methods | Welders are evaluated through various testing methods, including mechanical tests and non-destructive examinations, to ensure their welds meet quality standards. |

| Governing Standards | This form is often governed by standards such as AWS D1.1 and AWS B2.1, which outline the requirements for welding qualifications. |

| Variable Qualifications | Welders can qualify for different welding processes and positions, such as manual or automatic, and various joint configurations. |

| Certification | The record must be signed by a Certified Welding Inspector (CWI), confirming that all testing was performed according to the required standards. |

Key takeaways

Here are some important takeaways for filling out and using the Welder Performance Qualification Record form:

- Accurate Information: Always ensure that the welder's name, ATF number, and test number are filled out correctly. This information is crucial for identification.

- Social Security Number: Include the welder's Social Security number. This helps with record-keeping and verification.

- Reference WPS Number: Document the reference WPS (Welding Procedure Specification) number. It connects the qualification to the specific welding procedure used.

- Qualification Range: Clearly indicate the qualification range, including the code or specification used. This provides context for the test results.

- Welding Process: Specify the welding process and type, such as manual or semiautomatic. This affects the qualification and application of the weld.

- Test Results: Record mechanical test results carefully. This includes guided mechanical testing and any relevant figures.

- Non-Destructive Examination: Document the results of non-destructive examinations, like radiographic testing. This adds credibility to the qualification.

- Visual Inspection: Note the results of the visual inspection. Indicate whether the weld passed or failed, along with the reason for failure if applicable.

- Certification: Ensure that the form is signed by a Certified Welding Inspector (CWI). This signature verifies that the qualification was conducted properly.

Other PDF Templates

Alabama Sports Physical Form - Sections of the form are tailored to specific sports, enhancing its relevance to the athlete's chosen activities.

When engaging in the sale of a mobile home, it is vital to have a comprehensive understanding of the necessary documentation, including the New York Mobile Home Bill of Sale form, which serves as essential proof of ownership transfer. For those seeking a reliable template to facilitate this process, you can find one at newyorkform.com/free-mobile-home-bill-of-sale-template/, ensuring clarity and legality in your transaction.

Do I Need to Remove Lienholder From Title - Incorporating the holder’s mailing address is essential for any future correspondence concerning the property.

Example - Welder Performance Qualification Record Form

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

|

Welder’s Name: |

|

|

|

|

ATF No: |

|

Test No. |

||||||

|

Welder’s SS No. |

|

Date: |

|

|

Reference WPS No: |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

VARIABLE |

|

|

QUALIFICATION TEST DETAIL |

|

|

QUALIFICATION RANGE* |

|

|||||

|

Code or Specification Used: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Welding Process and Type: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Manual |

Semiautomatic |

|

|

Manual |

|

Semiautomatic |

|||

|

|

|

|

|

Mechanized |

Automatic |

|

|

Mechanized |

Automatic |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

Backing: |

|

|

|

Used |

Not Used |

|

|

Required if used |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Metal |

Spec/P or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Plate/Pipe Thickness – Groove |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Plate/Pipe Thickness – Fillet |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Groove |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Fillet |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filler Metal |

Specification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Classification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Consumable Insert |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Penetration Enhancing Flux |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Deposited Weld Metal Thickness |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Current/Polarity & Current Range |

|

Type/Polarity: |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Range: |

Amperes |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Metal Transfer Mode (GMAW or FCAW) |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Torch Shielding Gas |

|

Type: |

|

Flow: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

Root Shielding Gas |

|

NA Type: |

Flow: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

Position(s) |

|

|

|

Test Position(s) (1G, 2G, etc.): |

|

|

Qualified Position(s) (F, H, V, O, or All) |

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Vertical Progression |

|

Uphill |

Downhill |

|

|

Uphill |

Downhill |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* NOTE: Insert NA for Variables that are identified as

|

|

|

|

MECHANICAL TEST RESULTS |

|

|

||

|

Type And Figure No. |

|

|

Results |

|

Type And Figure No. |

Results |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guided mechanical Testing Conducted By: |

|

Date: |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

NONDESTRUCTIVE EXAMINATION RESULTS |

|

|

|||

|

Radiographic Results: |

|

|

|

Report No. |

|

|

|

|

|

|

|

|

|

|

||

|

Radiographic Testing Conducted By: |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welding Witnessed By: |

|

|

|

Visual Inspection: Pass |

Fail (reason |

) |

|

|

|

|

|

|||||

|

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with |

|||||||

|

the requirements of: AWS D1.1- |

, AWS B2.1- |

Other: |

|

|

|||

|

|

|

|

|

|

|||

|

Date Qualified: |

|

ATF Name and Number: |

|

|

|||

|

|

|

|

Signed By: |

CWI No. |

|

||

|

|

|

|

|

|

|

||

ATF WPQR Blank Form |

|

|

1 |

|

|

|||

Detailed Instructions for Writing Welder Performance Qualification Record

Filling out the Welder Performance Qualification Record form is an essential step in documenting a welder's qualifications. This process ensures that all necessary information is accurately captured, which can be crucial for future employment opportunities or compliance with industry standards. Follow these steps carefully to complete the form.

- Welder's Information: Start by entering the welder’s name, ATF number, and Social Security number. Include the date of the test and the reference WPS number.

- Qualification Test Details: Fill in the code or specification used, and specify the welding process and type (manual, semiautomatic, mechanized, or automatic).

- Backing: Indicate whether backing was used or not, and note if it was required.

- Base Metal Information: Provide the specification or P/M number, and the thickness of the base metal for both groove and fillet welds. Include the outside diameter for pipes if applicable.

- Filler Metal: Enter the specification number, classification number, and diameter of the filler metal. Indicate if a consumable insert or penetration enhancing flux was used.

- Deposited Weld Metal: Specify the thickness of the deposited weld metal, current/polarity, and the current range.

- Metal Transfer Mode: State the metal transfer mode (GMAW or FCAW) and provide details for the torch shielding gas type and flow rate.

- Root Shielding Gas: If applicable, note the type and flow rate of the root shielding gas.

- Test Positions: List the test positions (1G, 2G, etc.) and the qualified positions (F, H, V, O, or All). Indicate the vertical progression (uphill or downhill).

- Mechanical Test Results: Record the type and figure number of the mechanical tests conducted, along with the results.

- Non-Destructive Examination Results: Fill in the radiographic results and report number. Include the name of the person who conducted the radiographic testing and the name of the welding witness.

- Visual Inspection: Indicate whether the visual inspection passed or failed, and provide a reason if it failed.

- Certification: Certify that the statements in the record are correct. Fill in the date qualified, ATF name, and number. Ensure the form is signed by the CWI along with their number.

Documents used along the form

The Welder Performance Qualification Record (WPQR) is an essential document that certifies a welder's skills and qualifications. However, several other forms and documents are often used in conjunction with the WPQR to ensure comprehensive documentation and compliance with industry standards. Below is a list of these important documents, each serving a unique purpose in the qualification process.

- Welding Procedure Specification (WPS): This document outlines the specific welding processes, materials, and techniques that a welder must follow. It serves as a guide for the welder to ensure that all work meets the required standards.

- Welder Qualification Test Record (WQTR): Similar to the WPQR, this record details the results of a welder's qualification tests. It includes information about the tests performed and their outcomes, confirming that the welder is qualified for specific tasks.

- Non-Destructive Testing (NDT) Reports: These reports provide results from tests conducted to evaluate the integrity of welds without causing damage. Common methods include radiographic, ultrasonic, and magnetic particle testing.

- Promissory Note - A legal document that serves as a written promise to pay a certain amount at a specified time, offering clarity in financial transactions. For resources regarding templates, visit NY Templates.

- Material Certification Documents: These documents verify the quality and specifications of the materials used in welding. They ensure that the base and filler metals meet industry standards.

- Inspection Reports: After the welding process, inspection reports are generated to document the results of visual inspections and any other assessments. These reports indicate whether the welds meet the required quality standards.

- Quality Control Plan (QCP): A QCP outlines the procedures and standards for maintaining quality throughout the welding process. It ensures that all aspects of production meet regulatory and safety requirements.

- Training Records: These documents provide evidence of the training and continuing education that welders have completed. They are important for demonstrating ongoing competency and compliance with industry standards.

Utilizing these forms and documents alongside the Welder Performance Qualification Record ensures a thorough and compliant welding process. Each document plays a vital role in maintaining quality and safety in welding operations, ultimately contributing to successful project outcomes.