Get Dot Vehicle Inspection Form in PDF

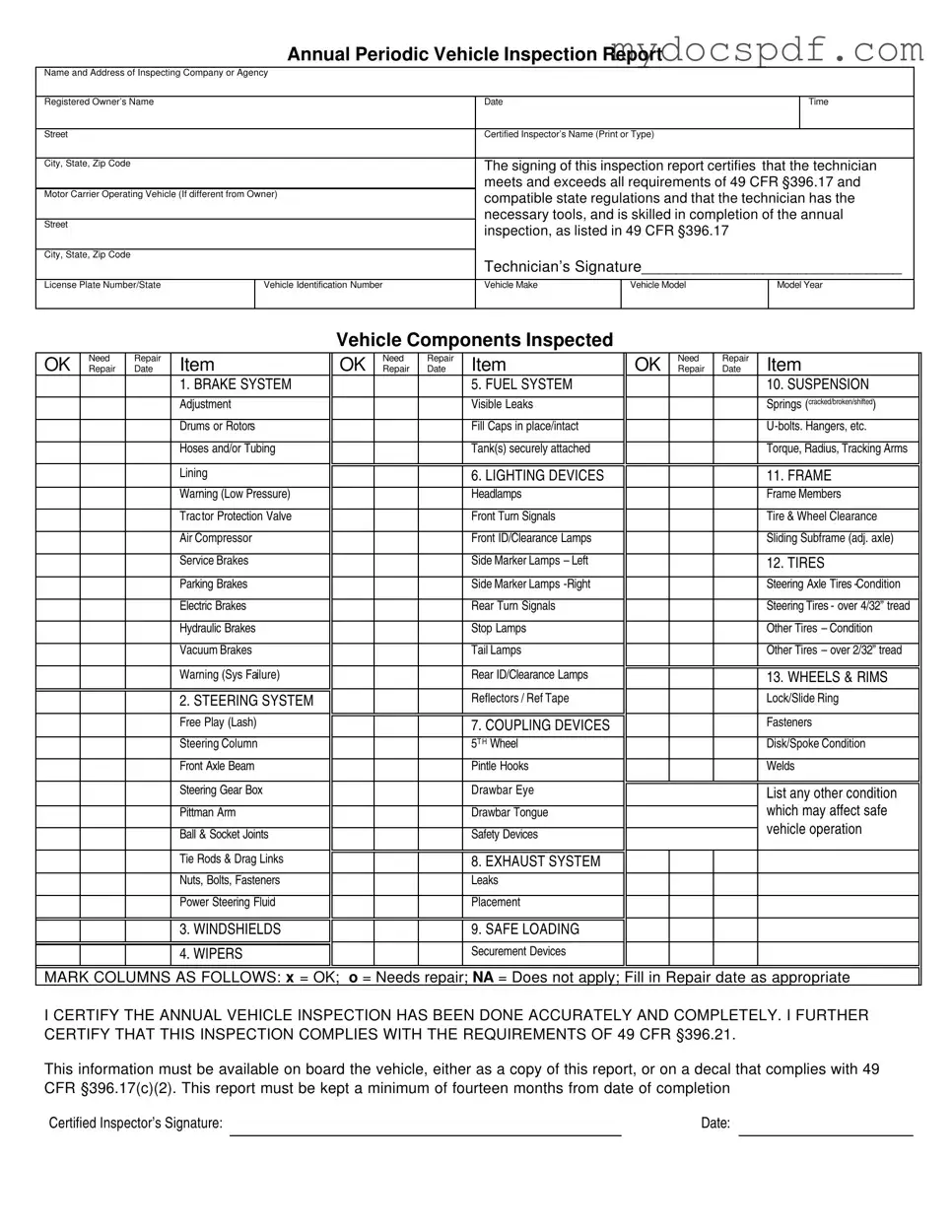

The DOT Vehicle Inspection form is a crucial document for ensuring the safety and compliance of commercial vehicles on the road. This form is used during the annual periodic vehicle inspections mandated by federal regulations. It captures essential information about the vehicle, including the name and address of the inspecting company, the registered owner's details, and the date and time of the inspection. A certified inspector must complete the form, affirming that they meet the qualifications outlined in 49 CFR §396.17. The inspection covers various vehicle components, such as the brake system, steering system, lighting devices, and tires. Each component is marked as either "OK" or "Needs Repair," with spaces provided to record repair dates. Additionally, the form includes sections for documenting the qualifications of the inspector and ensuring that the inspection complies with federal standards. Keeping this report on board the vehicle is essential, as it must be available for review and retained for at least fourteen months. This comprehensive approach helps maintain safety standards and promotes accountability within the trucking industry.

Dos and Don'ts

When filling out the DOT Vehicle Inspection form, it’s essential to approach the task with care and attention. Here are five things you should and shouldn’t do:

- Do ensure that all sections of the form are completed accurately. Missing information can lead to compliance issues.

- Do use clear and legible handwriting or type the information. This helps prevent misunderstandings.

- Do double-check the vehicle identification number (VIN) and license plate details. Errors here can complicate records.

- Do mark the condition of each vehicle component accurately. Use the correct symbols: x for OK, o for needs repair, and NA for not applicable.

- Do keep a copy of the completed form on board the vehicle, as required by regulations.

- Don’t leave any required fields blank. Incomplete forms can result in penalties during inspections.

- Don’t use abbreviations or unclear terms. Clarity is key for anyone reviewing the form.

- Don’t rush through the inspection process. Take the time to thoroughly assess each component.

- Don’t forget to include the technician's signature and date. This validates the inspection.

- Don’t ignore the importance of proper training and qualifications for the inspector. Ensure that the person filling out the form meets all necessary criteria.

Document Attributes

| Fact Name | Description |

|---|---|

| Purpose of the Form | The DOT Vehicle Inspection form is used to ensure that commercial vehicles meet safety standards. This annual report helps maintain vehicle safety and compliance with federal regulations. |

| Governing Laws | This form is governed by 49 CFR §396.17 and §396.21, which outline the requirements for vehicle inspections and the qualifications of inspectors. |

| Inspector Qualifications | Inspectors must understand inspection criteria and possess relevant training or experience. They should meet the qualifications set forth in 49 CFR §396.19. |

| Record Keeping | Inspection reports must be kept for a minimum of fourteen months. They should be available on board the vehicle, either as a report copy or a compliant decal. |

Key takeaways

Filling out the DOT Vehicle Inspection form is an essential part of maintaining vehicle safety and compliance. Here are key takeaways to keep in mind:

- The form must be filled out completely, including the name and address of the inspecting company, the registered owner's name, and the date and time of the inspection.

- Ensure the certified inspector’s name is printed clearly. This helps to verify qualifications and accountability.

- Each vehicle component must be inspected and marked as either OK, Needs Repair, or Does Not Apply.

- Be diligent about filling in repair dates for any components that need attention. This keeps a clear record of maintenance.

- Keep the inspection report on board the vehicle, either as a copy or on a decal, as required by regulations.

- The report must be retained for a minimum of fourteen months from the date of completion.

- Inspectors must be qualified, understanding the criteria set forth in federal regulations and capable of identifying defective components.

- Documentation of the inspector’s qualifications should be maintained and readily available for review.

- Brake inspectors have specific qualifications that must be met to ensure safe brake maintenance and inspections.

- Regular inspections not only ensure compliance but also enhance overall vehicle safety for drivers and others on the road.

By adhering to these guidelines, you help ensure that your vehicle remains safe and compliant with federal regulations.

Other PDF Templates

Direction to Pay Form Contractor - Complete this form to allow the insurance company to process claims efficiently.

The Texas Affidavit of Correction form serves as a legal document that allows individuals to correct mistakes in public records. This form is essential for ensuring that inaccuracies, such as typographical errors or incorrect information, are amended properly. By submitting this affidavit, individuals can maintain the integrity of their official documents and public records. For those seeking an effective way to handle such corrections, resources like Texas Forms Online can be invaluable.

Aao Form - You’ll need to indicate your patient cooperation level to support your ongoing care.

Example - Dot Vehicle Inspection Form

Annual Periodic Vehicle Inspection Report

Name and Address of Inspecting Company or Agency

Registered Owner’s Name |

|

Date |

|

|

Time |

|

|

|

|

|

|

Street |

|

Certified Inspector’s Name (Print or Type) |

|

|

|

|

|

|

|

|

|

City, State, Zip Code |

|

The signing of this inspection report certifies that the technician |

|||

|

|

meets and exceeds all requirements of 49 CFR §396.17 and |

|||

Motor Carrier Operating Vehicle (If different from Owner) |

compatible state regulations and that the technician has the |

||||

|

|

||||

|

|

necessary tools, and is skilled in completion of the annual |

|||

Street |

|

inspection, as listed in 49 CFR §396.17 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

City, State, Zip Code |

|

|

|

|

|

|

|

Technician’s Signature______________________________ |

|||

|

|

|

|

|

|

License Plate Number/State |

Vehicle Identification Number |

Vehicle Make |

Vehicle Model |

Model Year |

|

|

|

|

|

|

|

Vehicle Components Inspected

OK |

Need |

Repair |

Item |

OK |

Need |

Repair |

Item |

OK |

Need |

Repair |

Item |

|

Repair |

Date |

Repair |

Date |

Repair |

Date |

|

||||||

|

|

|

1. BRAKE SYSTEM |

|

|

|

5. FUEL SYSTEM |

|

|

|

10. SUSPENSION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjustment |

|

|

|

Visible Leaks |

|

|

|

Springs (cracked/broken/shifted) |

|

|

|

|

Drums or Rotors |

|

|

|

Fill Caps in place/intact |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hoses and/or Tubing |

|

|

|

Tank(s) securely attached |

|

|

|

Torque, Radius, Tracking Arms |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lining |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6. LIGHTING DEVICES |

|

|

|

11. FRAME |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning (Low Pressure) |

|

|

|

Headlamps |

|

|

|

Frame Members |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tractor Protection Valve |

|

|

|

Front Turn Signals |

|

|

|

Tire & Wheel Clearance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Air Compressor |

|

|

|

Front ID/Clearance Lamps |

|

|

|

Sliding Subframe (adj. axle) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Service Brakes |

|

|

|

Side Marker Lamps – Left |

|

|

|

12. TIRES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parking Brakes |

|

|

|

Side Marker Lamps |

|

|

|

Steering Axle Tires |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electric Brakes |

|

|

|

Rear Turn Signals |

|

|

|

Steering Tires - over 4/32” tread |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hydraulic Brakes |

|

|

|

Stop Lamps |

|

|

|

Other Tires – Condition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vacuum Brakes |

|

|

|

Tail Lamps |

|

|

|

Other Tires – over 2/32” tread |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning (Sys Failure) |

|

|

|

Rear ID/Clearance Lamps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13. WHEELS & RIMS |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reflectors / Ref Tape |

|

|

|

Lock/Slide Ring |

|

|

|

|

2. STEERING SYSTEM |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Free Play (Lash) |

|

|

|

|

|

|

|

Fasteners |

|

|

|

|

|

|

|

7. COUPLING DEVICES |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steering Column |

|

|

|

5T H Wheel |

|

|

|

Disk/Spoke Condition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Front Axle Beam |

|

|

|

Pintle Hooks |

|

|

|

Welds |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steering Gear Box |

|

|

|

Drawbar Eye |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

List any other condition |

|

||

|

|

|

|

|

|

|

|

|

|

|

which may affect safe |

|

|

|

|

Pittman Arm |

|

|

|

Drawbar Tongue |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

vehicle operation |

|

|

|

|

Ball & Socket Joints |

|

|

|

Safety Devices |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tie Rods & Drag Links |

|

|

|

8. EXHAUST SYSTEM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nuts, Bolts, Fasteners |

|

|

|

Leaks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power Steering Fluid |

|

|

|

Placement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. WINDSHIELDS |

|

|

|

9. SAFE LOADING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Securement Devices |

|

|

|

|

|

|

|

|

4. WIPERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MARK COLUMNS AS FOLLOWS: x = OK; o = Needs repair; NA = Does not apply; Fill in Repair date as appropriate

I CERTIFY THE ANNUAL VEHICLE INSPECTION HAS BEEN DONE ACCURATELY AND COMPLETELY. I FURTHER CERTIFY THAT THIS INSPECTION COMPLIES WITH THE REQUIREMENTS OF 49 CFR §396.21.

This information must be available on board the vehicle, either as a copy of this report, or on a decal that complies with 49 CFR §396.17(c)(2). This report must be kept a minimum of fourteen months from date of completion

Certified Inspector’s Signature: |

|

Date: |

|

|

|

INSPECTOR QUALIFICATIONS

Certification — 49 CFR §396.19

Motor carriers are responsible for ensuring that individual(s) performing an annual inspection under §396.17 are qualified as follows:

•Understands the inspection criteria set forth in Part 393 and Appendix G and can identify defective components

•Is knowledgeable of and has mastered the methods, procedures, tools and equipment used when performing an inspection

•Is capable of performing an inspection by reason of experience, training, or both, and qualifies in one of the following categories (check all that apply):

I.___ Successfully completed a State or Federal training program or has certificate from a State or Canadian Province which qualifies the person to perform commercial vehicle safety inspections.

Specify: _______________________________________

II.___ Have a combination of training or experience totaling at least one year as follows (check all that apply):

a.___ Participation in a truck

Where and Date: _____________________________________________________

b.___ (years) experience as a mechanic or inspector in a motor carrier maintenance program.

Name and Date: _____________________________________________________

c.___ (years) experience as a mechanic or inspector in truck maintenance at a commercial garage, fleet leasing company, or similar facility.

Name of Facility and Dates: ____________________________________________

d.___ (years) experience as a commercial vehicle inspector for a State, Provincial, or Federal Government.

Where and Dates: ____________________________________________________

I certify the above information is true and accurate to the best of my knowledge.

Employee ______________________________________ |

________________ |

Signature of Mechanic/Inspector |

Date |

Motor Carrier/Company ____________________________________ |

________________ |

Signature of Employer/Supervisor |

Date |

Evidence of Inspector Qualification is on file at:

_______________________________

BRAKE INSPECTOR QUALIFICATIONS

Certification — 49 CPR §396.25

“Brake Inspector” means any employee of a motor carrier who is responsible for ensuring all brake inspections, maintenance, service, or repairs to any commercial motor vehicle, subject to the motor carrier’s control, meet the applicable Federal standards.

No motor carrier shall require or permit any employee who does not meet minimum brake inspector qualifications to be responsible for the inspection, maintenance, service or repairs of any brakes on its commercial motor vehicles.

Minimum Qualifications

•Understands and can perform brake service and inspection

•Is knowledgeable of and has mastered the methods, procedures, tools and equipment necessary to perform brake service and inspection

•Is capable of performing brake service or inspection by reason of experience, training, or both, and qualifies in one of the following categories (check all that apply):

I.___Has successfully completed an apprenticeship program sponsored or approved

by a State, Canadian Province, a Federal agency or labor union, or has a certificate from a State or Canadian Province which qualifies the person to perform brake service or inspections.

Specify: ________________________________________________________________

II.___ Has

a.___Participation in a brake maintenance or inspection training program sponsored by a brake or vehicle manufacturer or similar commercial training program.

Where and Date:_______________________________________________

b.___ (years) experience performing brake maintenance or inspection in a motor carrier maintenance program.

Name and Date:_______________________________________________

c.___ (years) experience performing brake maintenance or inspection at a commercial garage, fleet leasing company, or similar facility.

Name of Facility and Dates:______________________________________

I certify the above information is true and accurate to the best of my knowledge.

Employee ______________________________________ |

________________ |

Signature of Mechanic/Inspector |

Date |

Motor Carrier/Company ____________________________________ |

________________ |

Signature of Employer/Supervisor |

Date |

Evidence of Inspector Qualification is on file at:

_______________________________

Detailed Instructions for Writing Dot Vehicle Inspection

Completing the DOT Vehicle Inspection form is a straightforward process that ensures your vehicle meets safety standards. This form captures essential information about the vehicle and the inspection process. Follow these steps to fill it out accurately.

- Enter the Name and Address of the inspecting company or agency at the top of the form.

- Fill in the Registered Owner’s Name and the Date of the inspection.

- Record the Time of the inspection.

- Provide the Street, City, State, Zip Code of the registered owner.

- Print or type the Certified Inspector’s Name.

- If different from the owner, fill in the Motor Carrier Operating Vehicle details.

- Enter the License Plate Number/State and Vehicle Identification Number.

- Specify the Vehicle Make, Vehicle Model, and Model Year.

- Inspect the vehicle components listed and mark each item as follows: x for OK, o for Needs repair, and NA for Does not apply.

- For any items that need repair, fill in the Repair Date.

- List any other conditions that may affect safe vehicle operation.

- Sign and date the form in the designated areas for the Certified Inspector.

- Ensure that the information is available on board the vehicle, either as a copy of this report or on a compliant decal.

Documents used along the form

The DOT Vehicle Inspection form is a critical document that ensures the safety and compliance of commercial vehicles. However, it is often accompanied by other important forms and documents that further support the inspection process and regulatory requirements. Below is a list of additional forms that may be used alongside the DOT Vehicle Inspection form.

- Vehicle Maintenance Record: This document tracks all maintenance and repair activities performed on the vehicle. It provides a history that can be useful for inspections and helps ensure that all necessary repairs are completed in a timely manner.

- Trailer Bill of Sale: This document is essential when transferring ownership of a trailer, ensuring proper identification and the details of the buyer and seller are recorded. For a template, you can visit NY Templates.

- Driver Vehicle Inspection Report (DVIR): This report is completed by the driver at the beginning or end of their shift. It documents any defects or issues found during a pre-trip or post-trip inspection, ensuring that the vehicle is safe for operation.

- Annual Inspection Certificate: After passing the DOT Vehicle Inspection, this certificate is issued to confirm that the vehicle meets federal safety standards. It must be kept on file and may need to be presented during roadside inspections.

- Maintenance Schedule: This document outlines the routine maintenance tasks required for the vehicle, including oil changes, tire rotations, and brake inspections. Adhering to this schedule helps maintain vehicle performance and safety.

- Accident Report Form: In the event of an accident, this form documents the details of the incident, including the parties involved, damages, and any injuries. It is essential for insurance claims and legal proceedings.

- Fuel Purchase Log: This log tracks fuel purchases for the vehicle. It is often used for budgeting and can help identify fuel efficiency trends over time.

- Driver Qualification File (DQF): This file contains essential information about the driver, including their training, certifications, and driving record. It ensures that the driver meets the necessary qualifications to operate the vehicle safely.

- Hazardous Materials Registration: For vehicles transporting hazardous materials, this registration is required. It ensures compliance with regulations and provides important information about the materials being transported.

- Weight Station Receipts: These receipts are obtained when a vehicle passes through a weigh station. They confirm that the vehicle is within legal weight limits and can be important for compliance documentation.

- Inspection Checklist: This checklist outlines specific items that need to be inspected during the vehicle inspection process. It serves as a guide for inspectors to ensure that all necessary components are evaluated.

Each of these documents plays a vital role in maintaining safety and compliance within the transportation industry. Keeping them organized and up-to-date not only helps meet regulatory requirements but also enhances the overall safety of commercial operations.